The Super Compact 2.1 is the smallest in capacity and size of the whole range of Dal Prete compact systems.

WHO WE DESIGNED IT FOR

• If you have a new stone laboratory and you install only the machines strictly necessary: bridge saw and manual polisher.

• If you have a company that wants to start a specific production using one or two machine centers that need a lot of water but do not produce large quantities of sludge.

FEATURES AND ADVANTAGES

Single block of only 4 m² (13 ft²).

Space saving.

Square shape.

Maximized decanter volume.

Automatic operations.

Save time and reduce human error.

Integrated clarification and dehydration.

Ease of use.

The waste product is dehydrated sludge.

The working place is always clean.

10″ touch screen with intuitive software.

Control via LAN.

IP55 protection against dust and water jets.

Free space under the filter press.

Shipped as a single piece.

CUSTOMIZATIONS

• Insulation of the plant, if you place it outside.

• Integrated system of tanks, for dirty and clarified water.

DPURE Software

DPURE is the Dal Prete software created and optimized over the years, in order to adapt to the real needs of customers. Its customized solutions allow to schedule activities and manage clarification and dehydration operations more quickly and efficiently.

Increased automation guarantees a systematic and error-free execution of the different processes, enabling a high level of customization of the functionalities according to the specific objectives of the production.

The Super Compact 2.1 offers excellent performances in small spaces. It is ideal for managing a limited number of machines and working efficiently even with small production volumes.

Thanks to its essential and intuitive interface, the DPURE software installed on the Super Compact 2.1 simplifies plant management and eliminates the need for a dedicated operator.

MAIN FEATURES

• 10” touch screen with display and control of all plant components.

• LAN connection for telematic assistance.

• Complete and automated control of clarification and dehydration cycles.

• Planning of dehydration cycles in line with production needs.

• Complete management of alarms with alerts on the integrated touch screen and optionally also via sms.

• Possibility of software customization.

Clarified water production

150 l/min

40 US gal/min

Total installed power

5,0 kW

Transport space

3 m on a truck or container

10 ft on a truck or container

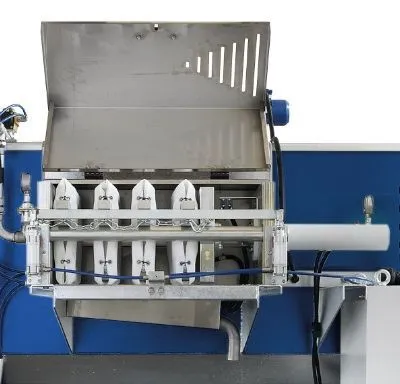

Filter press plates

4

Plates dimensions

300 x 300 mm

1 x 1 ft

Transport space

0,8 m³/ 8h

2,6 ft³/ 8h

We use cookies to improve your experience. Privacy Policy.